The articles of the current edition are available on the new site.

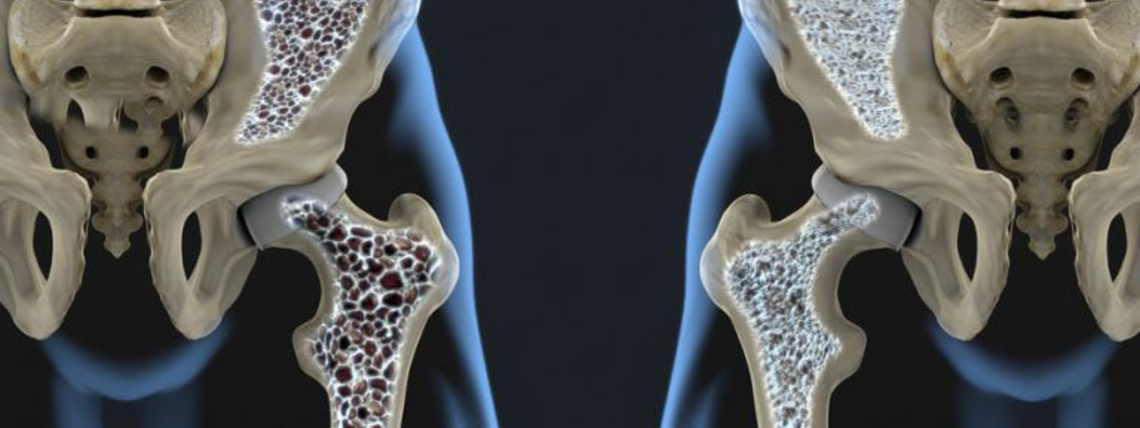

Osteoporosis (“porous bone”) is a very common bone disease, it is more frequent after menopause and with aging but it can occur also at younger age. It occurs when the body loses too much bone, as a result bones become weak and brittle - so brittle that a fall or even mild stresses such as bending over or coughing can cause a fracture. It has been calculated that an osteoporotic fracture occurs every 3 seconds in the world, and it is most likely to occur in the hip, spine or wrist, but other bones can also break. After a fracture, patients can lose their independence, suffer from chronic pain and become depressed, thus osteoporosis turns into an impressive socio-economic burden.

The GIOTTO project is funded by the European Union under the Horizon 2020 research and innovation programme, and it will exploit the most recent materials and manufacturing technological advancements to help healthcare systems fight the consequences of this disease. Medical doctors will work together with scientists and medical device producers to develop and test new solutions based on cutting edge technologies such as 3D printing and smart nano-biomaterials. Ad hoc devices will be designed for the different types of osteoporotic fractures stimulating bone regeneration while reducing bone loss.

In addition to 3D-printing and the most updated technologies for bone scaffold manufacturing, also the most advanced technologies will be put in place such as the nano-functionalisation for the smart release of active molecules. The use of additive manufacturing technologies will enable device personalisation to match and better align with the patient’s anatomy and fracture type. A further boost to meet patient specificity and needs will be provided through use of functionalised magnetic nanoparticles in order to allow controlled mechano-transduction. An Internet of Things platform will be developed to gather and collate measurable data inputs about device effectiveness and to provide decision support software as a service to improve the design, manufacture and clinical function of the proposed devices, ultimately managing the overall value chain. Safety and sustainability of the final solutions will guide the overall development since the beginning, though testing and the involvement of regulators.

GIOTTO project kick-off meeting was held in Brussels on February 4th and 5th 2019. Research partners are: Politecnico di Torino (Italy), Universitad Complutense de Madrid (Spain), Newcastle University (United Kingdom), Università di Pisa (Italy), Universiteit Maastricht (Netherlands), Dublin City University (Ireland) and Foundation for Research and Technology Hellas (Greece). Several industrial partners collaborate in the project: Fluidinova SA (Portugal), Tecnan (Spain), Cellink AB (Sweden), Novaicos SRLS (Italy), Biomech Innovations AG (Switzerland), Yodiwo (Greece) and BeWarrant (Belgium).